In today’s manufacturing landscape, the demand for precision and complexity in molded products has skyrocketed. To meet these exacting standards, manufacturers are turning to high-precision molds with multi-slide structures. These molds offer unparalleled versatility and efficiency, enabling the production of intricate parts with exceptional accuracy.

Understanding Multi-Slide Molds

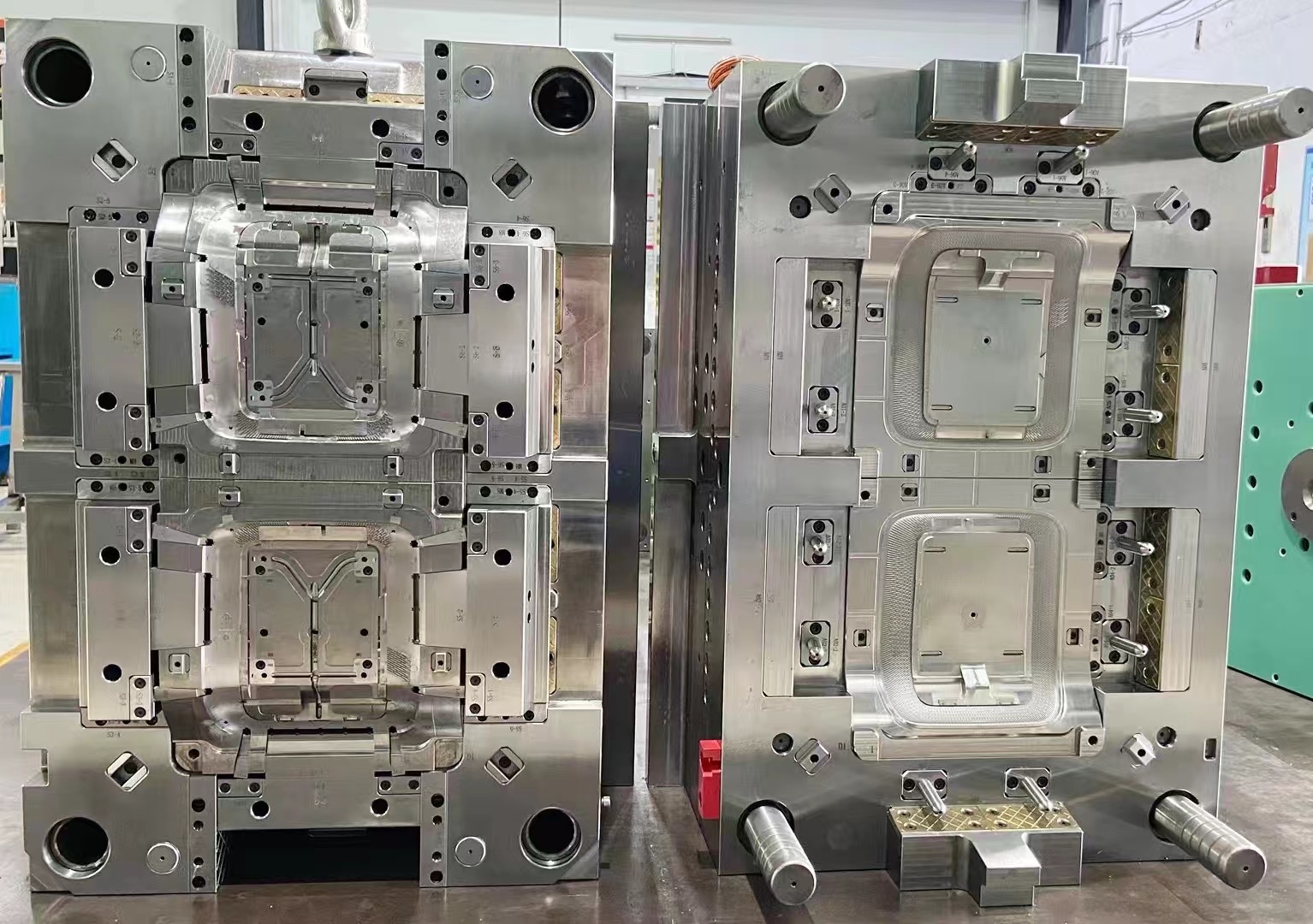

Multi-slide molds are a type of injection mold featuring multiple slides that can be moved independently or in combination. These slides allow for the creation of complex geometries and features that would be difficult or impossible to achieve with traditional single-slide molds.

Key Benefits of Multi-Slide Molds

- Enhanced Complexity: Multi-slide molds can create parts with intricate undercuts, side cores, and other complex features that are essential for many industries.

- Improved Efficiency: By reducing the number of required molding cycles, multi-slide molds can significantly increase production efficiency and lower costs.

- Greater Precision: The precise control over slide movements ensures that molded parts meet stringent tolerance requirements.

- Versatility: Multi-slide molds can be used to produce a wide range of products, from automotive components to consumer electronics.

Types of Multi-Slide Molds

- Side Action Slides: These slides move laterally, allowing for the creation of undercuts and side cores.

- Center Action Slides: These slides move inward from the center of the mold, enabling the production of intricate internal features.

- Angular Action Slides: These slides move at an angle, providing flexibility in creating complex geometries.

- Stacked Slides: Multiple slides are stacked on top of each other to create even more intricate parts.

Applications of Multi-Slide Molds

- Automotive Industry: Engine components, transmission parts, interior trim, and exterior panels.

- Electronics Industry: Connectors, enclosures, and small components.

- Medical Devices: Surgical instruments, implants, and diagnostic tools.

- Consumer Goods: Toys, appliances, and packaging.

Design Considerations for Multi-Slide Molds

- Slide Design: The design of the slides must ensure smooth movement and prevent binding or interference.

- Mold Base Selection: The mold base must be strong enough to support the forces generated by the slides.

- Ejection System: A reliable ejection system is essential for preventing part damage and ensuring consistent quality.

- Cooling System: An efficient cooling system is necessary to maintain precise temperature control and prevent warping or distortion.

Conclusion

High-precision molds with multi-slide structures are indispensable tools for modern manufacturing. By offering enhanced complexity, improved efficiency, greater precision, and versatility, these molds enable the production of a wide range of products that meet the most demanding standards. As technology continues to advance, we can expect to see even more innovative and sophisticated multi-slide mold designs in the future.